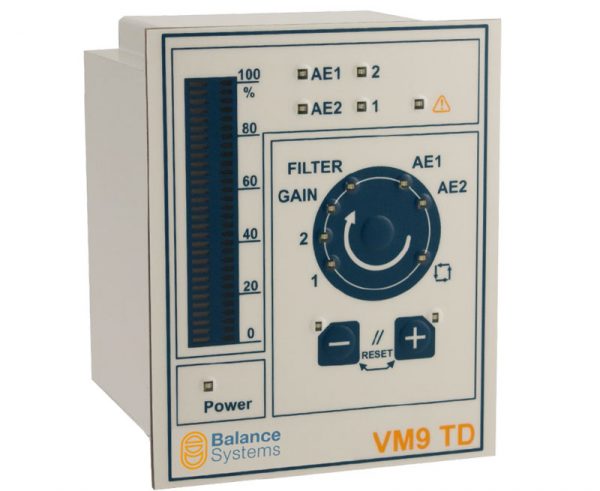

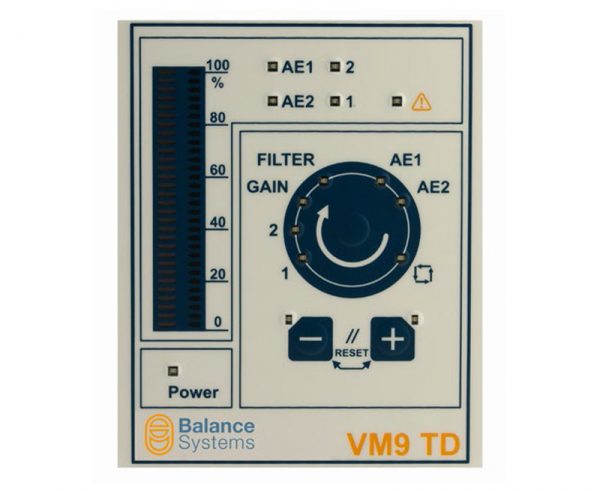

Product Description

| RANGE OF ACOUSTIC EMISSION SENSORS | |

|---|---|

| TYPE | MOUNTING |

| AE Ultrasonic | Static (machine table, work head body, tailstock body, dresser body, spindle body, etc.) |

| AE Single Point | Static (machine table, work head body, tailstock body, dresser body, spindle body, etc.) |

| AE nose (contactless) | Spindle nose (OD and ID grinding spindle, dressing spindle, etc.) |

| AE Built-in (contactless) | Built-in spindle (OD and ID grinding spindle, dressing spindle, etc.) |

| AE Ring (contactless) | Outside coaxial device to rotor (OD and ID grinding spindle, dressing spindle, work head, tailstock, etc.) |

| AE Fluid | Static and crossed by coolant (grinding area, dressing area, etc.) |