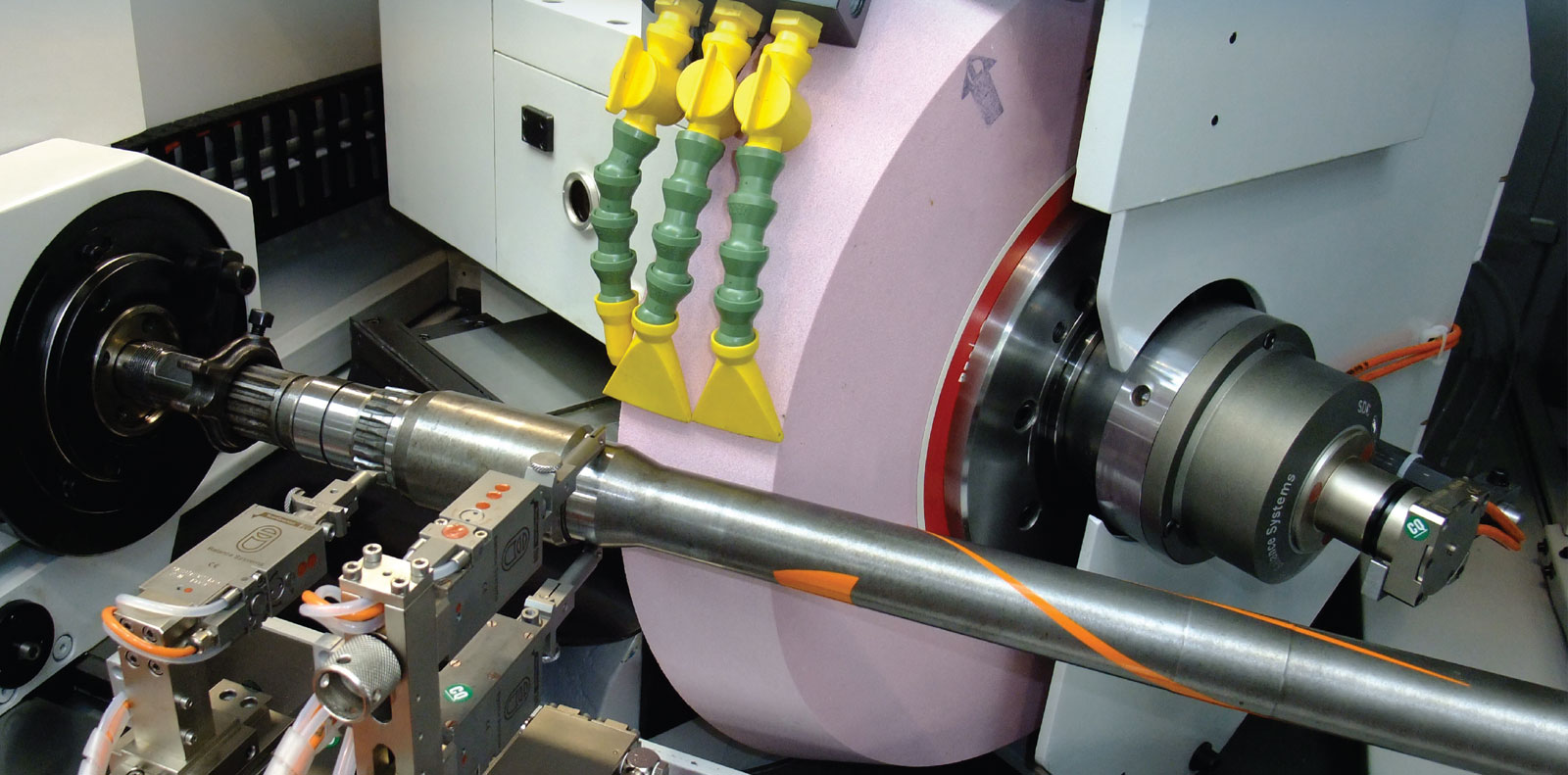

Balancing of the spindle and grinding wheel

The balancing of the spindle and grinding wheel is an essential operation to achieve the machining’s surface quality and to ensure a long life of a rotary components.

We offer a wide range of balancing systems based on balancing heads which can be installed externally or built-in the spindle. Control units are equipped with cable and contact less (no-link) solutions and provide constant vibration monitoring. Our newly designed “Absolute Balancer®”, state-of-the-art technology, is characterized by unprecedented performance levels in terms of execution speed and balancing precision on 1 and 2 plane.

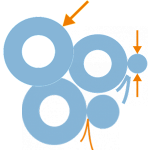

Balancing control of spindle in real time

Our monitoring system of the unbalance vibrations of the spindle-grinding wheel assembly allows to realize an effective control loop in real time, to guarantee the production quality and to extend components’ lifecycle (spindle, supports, grinding wheel, dressers). The use of high precision mechatronic actuators with refined control algorithms and contactless transmission techniques allows unmatched performances regarding quality, precision and runtimes to reduce the unbalance to microscopic values.