Product Description

Configuration

The VM15 System is available as:

Single-function

- VM15-B 1 plane balancing

- VM15-T Touch detection

- VM15-G In-process gauging

Dual-function

- VM15-BT 1 plane balancing and touch detector

- VM15-BG 1 plane balancing and in-process gauge

- VM15-TG Touch detector and in-process gauge

The typical installation includes

Control unit with all necessary functions, installed inside the electrical cabinet of the machine. The control unit is directly connected to the PLC/NCU in order to control in real time all the functions.

User remote interface supplied with an independent control panel, with a graphic display and multi-function keyboard with softkey

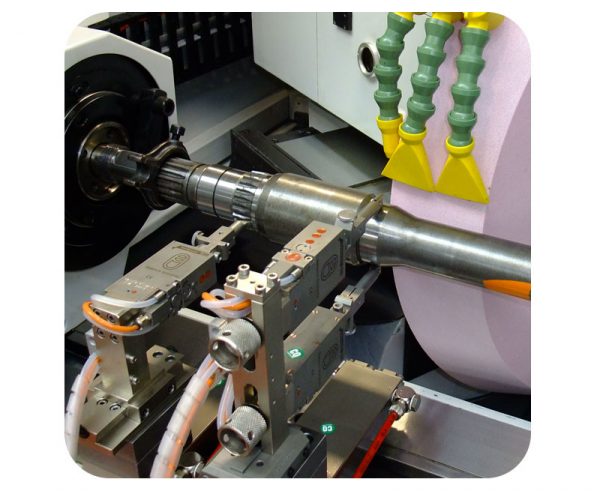

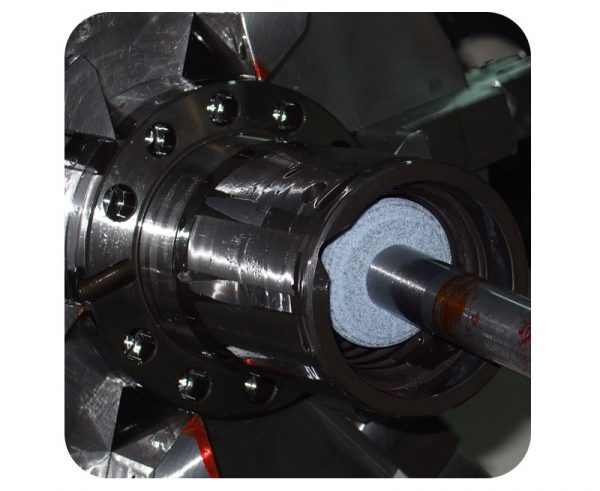

Sensors and actuators fitted on the machine in the working area