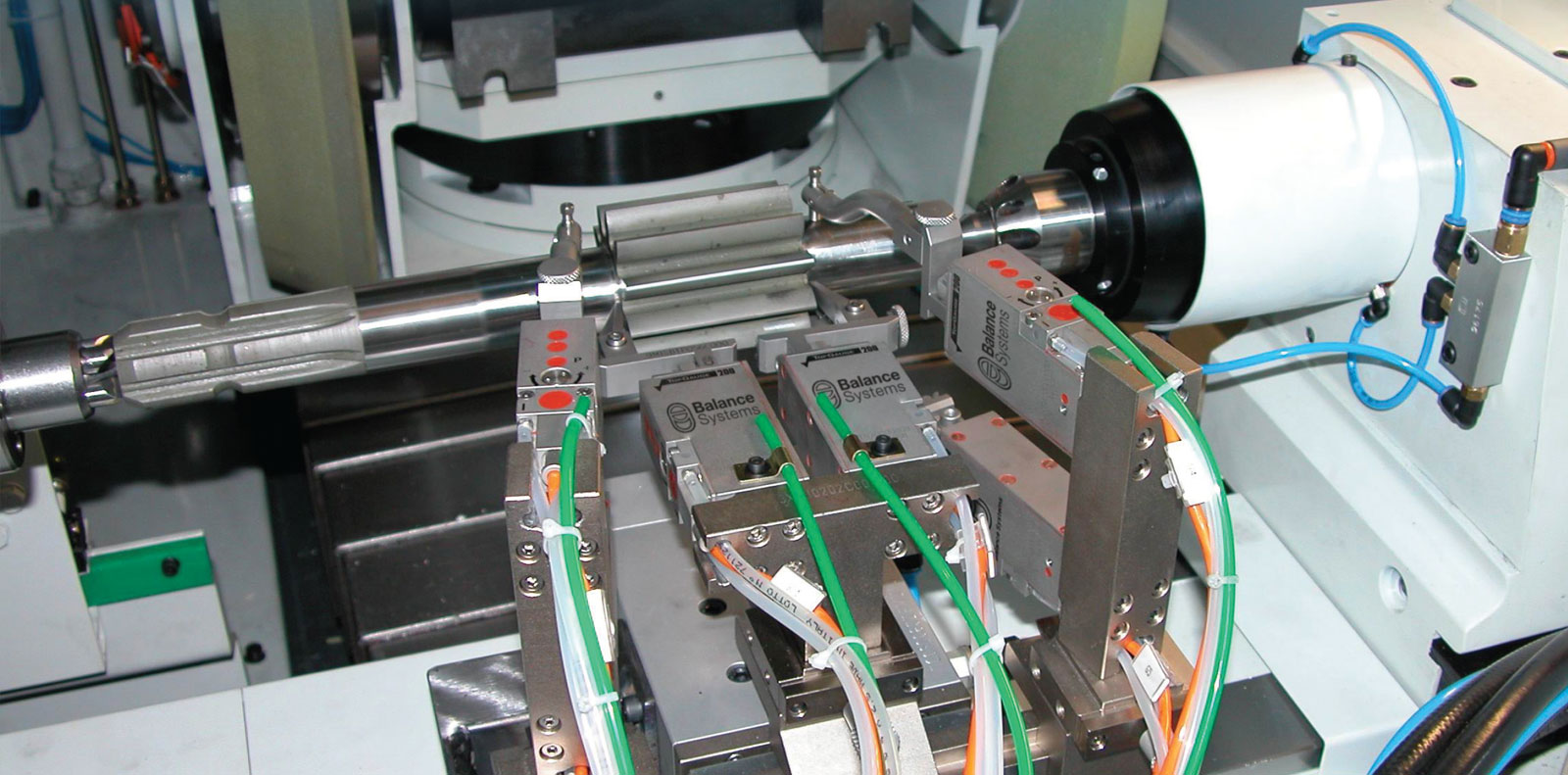

Gauging of grinding process: systems of Balance Systems

In high-volume production contexts, cycle-times and quality-steadiness matter. The in-process gauging system helps to save a lot of time per workpiece through the detection of the actual dimension of the part being grinded. This variable value, typically diameters, is used to automatically control the material removal based on the desired final dimension.

This presents a critical step towards the full optimization of grinding operations in a computer numerically controlled (CNC) environment.

In-process measuring systems

Our in-process measuring systems include:

- absolute measure of diameters

- comparative measure with master reference

- features to measure both continuous and interrupted surfaces (regular and irregular)

- roundness and shape analysis

- measure of external and internal diameters, thickness, overstock division, taper, flagging and more

- wide range of tools: slides, supports, arm, tracers and anti-crash systems

- part-programs defined for each type of work-piece to be produced

- automatic compensation for process correction

- special customized applications