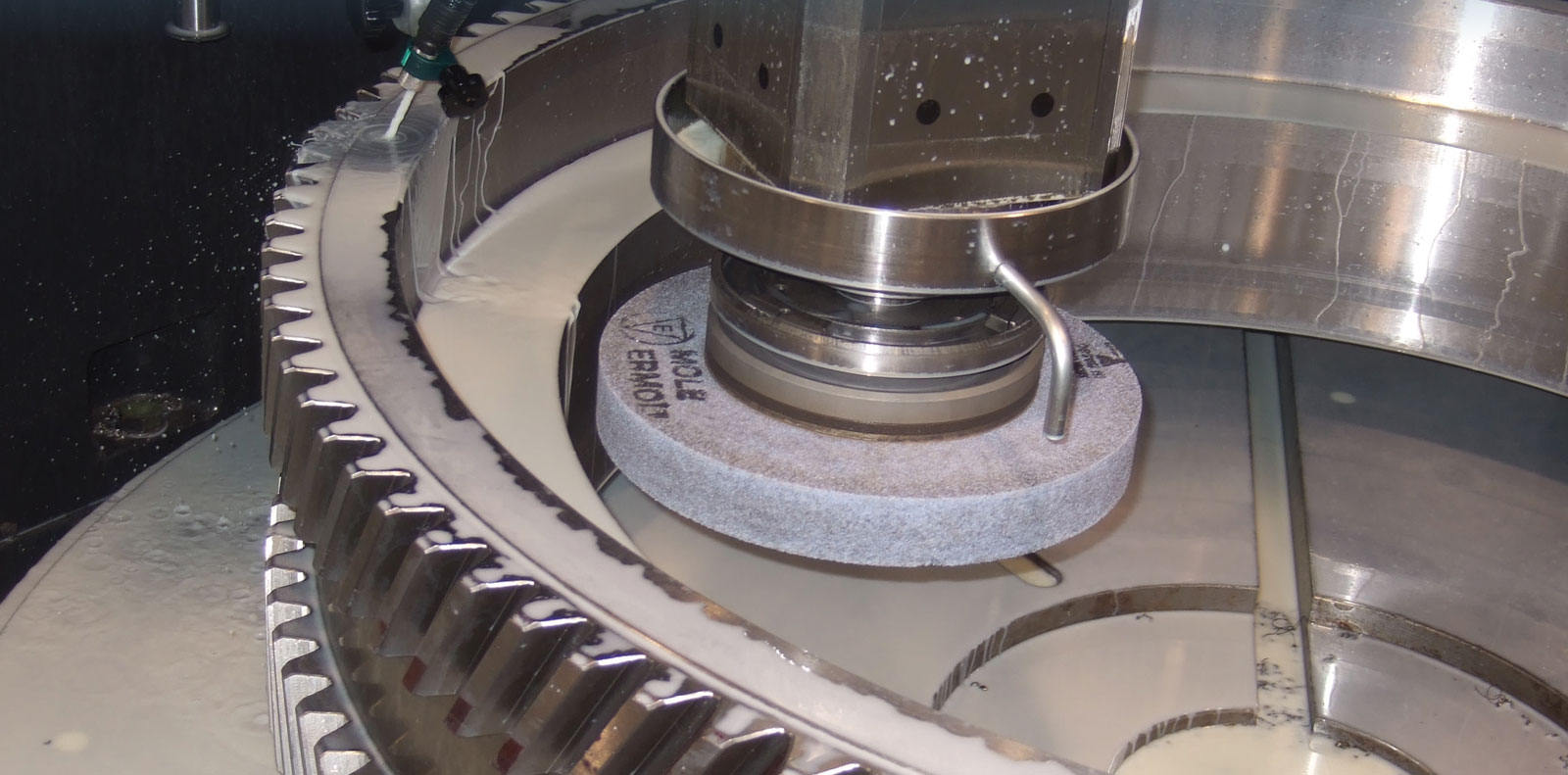

Control grinding wheels contact

The control of the grinding wheel balancing and its dresser allow to obtain a perfect profile also optimizing removal of the grinding wheel surface, which is evident by the increase in the tool life and reducing environmental impact.

The exact identification of the instant when the tool touches the work-piece is an essential information to minimize the cycle time. The use of such information allows to reduce the “air grinding” time, optimizing the axis infeed.

Control grinding wheel contact: Balance Systems sensors

At Balance Systems we offer a complete range of power sensors and acoustic emission (AE), that are able to:

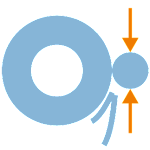

- detect sub-micrometric contacts (“gap” function)

- monitor constantly the work in progress preventing collision situations (“anti-crash” function)

- provide feedback signals for adaptive control.

Furthermore, these power sensors and AE sensors, that are stand-alone or built into the balancing head dedicated to the spindle-grinding-wheel, can be combined to a refined control unit that exploits advanced techniques of digital filtering.